BendSim

BendSim is software for programming

and simulating press brakes to maximize production efficiency.

BendSim is software for programming

and simulating press brakes to maximize production efficiency.

Being able to work with 3D engineering data is a crucial part of any modern sheet metal production workflow.

AutoPOL directly imports most major 3D CAD file formats.

It is not only the 3D model itself that will be imported. Also CAD specific properties will be read. These are maintained with the part throughout the process and can be used downstream for various purposes. For example quoting, planning and analysis.

2D CAD files can also be used by converting the flat pattern into a 3D model.

AutoPOL is independent software that supports most brands of press brakes. This means you can program all your press brakes from the same software.

Here is a list with samples of machine brands where AutoPOL is used to program them.

Even if your brand is not listed, please reach out to one of our resellers, as more machines are continuously added.

Or can be developed…

AutoPOL fits well in an Industry 4.0 environment

With the Industry 4.0 Data Sharing protocol any software system can extract information and data from AutoPOL. This can be, for example, part information or properties from the imported CAD file. This data can then be used for quoting, planning, analysis,

or anything else you can imagine.

AutoPOL fits well in an Industry 4.0 environment

With the Industry 4.0 Data Sharing protocol any software system can extract information and data from AutoPOL. This can be, for example, part information or properties from the imported CAD file. This data can then be used for quoting, planning, analysis,

or anything else you can imagine.

BendSim is available in two different product tiers, to suit different needs and budgets.

This way the small company with maybe just one press brake for internal use to the large manufacturer with many different machines in an Industry 4.0 integrated factory can find a suitable solutions.

You can compare the two tiers, BendSim & BendSim Pro, under Read more.

An add-on that enables you to automate the processing of parts or assemblies and connect your own software systems to remote control or extract data from AutoPOL.

An add-on that enables you to automate the processing of parts or assemblies and connect your own software systems to remote control or extract data from AutoPOL.

Being able to work with 3D engineering data is a crucial part of any modern sheet metal production workflow.

AutoPOL directly imports most major 3D CAD file formats.

It is not only the 3D model itself that will be imported. Also CAD specific properties will be read. These are maintained with the part throughout the process and can be used downstream for various purposes. For example quoting, planning and analysis.

2D CAD files can also be used by converting the flat pattern into a 3D model.

AutoPOL is independent software that supports most brands of press brakes. This means you can program all your press brakes from the same software.

Here is a list with samples of machine brands where AutoPOL is used to program them.

Even if your brand is not listed, please reach out to one of our resellers, as more machines are continuously added.

Or can be developed…

Accurl, Accurpress, Adira, Aliko, Alpmac, Amada, Automec, Baykal, Beyeler, BLM, Boschert, Bystronic, CBC, Cincinnati, Coastone, Colgar, Colly, Darley, Dener, Deratech, Durma, Dye, Edwards Pearson, EHT, Ermaksan, Farina, Finn-Power, Gade, Gasparini, Gilardi, Gizelis, Han’s, Hilalsan, Hindustan, HSG, Hurco, Hämmerle, Iturrospe, Jean Perrot, JFY, JMT (Durma), Jordi, LAG, LVD, Mecos, Metallkraft, Metfab, Murata, MVD, Newton, Piranha, Placke, Prima Power, Proteck, Pullmax, Ragos, Rico, RMT, Safan, SafanDarley, Salvagnini, Shaanxi Haven, Shenchong, SMD, STR, Trumpf, Ursviken, Vartek, Vicla, Vimercati, Warcom, Weinbrenner, Wysong, Yangli, Yawei, Yeh-Chiun.

AutoPOL fits well in an Industry 4.0 environment

With the Industry 4.0 Data Sharing protocol any software system can extract information and data from AutoPOL. This can be, for example, part information or properties from the imported CAD file. This data can then be used for quoting, planning, analysis,

or anything else you can imagine.

BendSim is available in two different product tiers, to suit different needs and budgets.

This way the small company with maybe just one press brake for internal use to the large manufacturer with many different machines in an Industry 4.0 integrated factory can find a suitable solution.

You can compare the two tiers, BendSim & BendSim Pro, under Read more.

An add-on that enables you to automate the processing of parts or assemblies and connect your own software systems to remote control or extract data from AutoPOL.

A 3D design tool for simple sheet metal parts, such as brackets, boxes and profiles.

This a suitable add-on for those who need a simple way to create basic 3D sheet metal parts.

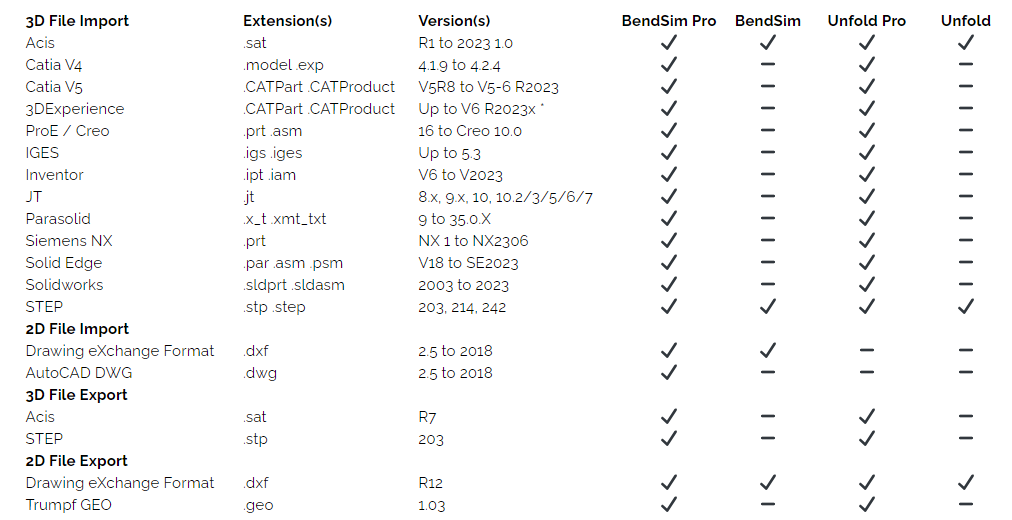

Here are all the different file formats that are included with different packages and which version is currently supported. With AutoPOL Bendsim and Bend0sim Pro you can convert flat patterns with bend lines into 3D files from the 2D files mentioned below. AutoPOL files (.polp) created and saved with Bendsim Pro / Unfold Pro cannot be opened with Bendsim / Unfold (non-Pro versions).

* 3DExperience (Catia V6) users should export their database objects as Catia V5 CATParts/CATProducts

System integrators can easily extract data and graphics from AutoPOL files.

That is done using a simple and well-documented protocol that gives access to part specific data along with manufacturing data. So basically anything from material, weight and thickness to cutting lengths, cycle time estimates and tooling used.

Also available are also images of the part and flat pattern to use as, for example, previews.

There are even 3D models of the part and flat pattern that can be shown by implementing our free AutoPOL AGX Graphics Viewer into your system.

With all of this made available, it is up to you to imagine and decide what you want to use it for.

But some common functionality that many develop is for example automation of quoting, manufacturability checks, production planning and performance evaluation.